Resource guide to direct marketing livestock and poultry

Important Announcement FlipHTML5 Scheduled Server Maintenance on GMT Sunday, June 26th, 2: FlipHTML5 site will be inoperative during the times indicated! A Resource Guide to Direct MarketingLivestock and Poultry Written by: Martha Goodsell, Fallow Hollow Deer Farm Tatiana Stanton, Cornell University Jim McLaughlin, Cornerstone Farm VenturesFunded in part by a Food and Industry Development Grant received from the New York State Department of Agriculture and Markets and through the contributions of NY Farms!

Resource Guide to Direct Marketing Livestock and Poultry TABLE OF CONTENTSIntroduction to Meat Regulation What is the difference? Who are the Responsible Parties? From the contemporary farm stand to the upscale grocery store Risk Management and Insurance Considerations for Farmers Selling Direct Introduction to Meat RegulationWhy we decided to do this project The purpose of this resource guide is to help New York farmers to better understand the currentregulations governing the slaughter, processing, and marketing of meat animals.

One way for farmers to realizehigher returns for their farm products is by taking over some of the traditional roles of middlemen or by shiftingcompletely to direct marketing. However, meat regulations are complex. Accurately interpreting the statutesgoverning the processing and sale of meat animals and their products is more formidable for us than for ourcounterparts in fruit and vegetable production.

Even experienced farmers can be confused by the regulations. Without a clear understanding of what is and is not permitted under current laws, many meat producers arehesitant to participate more directly in the marketing of their product. Instead, farmers may be confined to 1 contract growing livestock for large corporate packers, or 2 selling slaughter animals through a shrinkingnumber of local auctions and dealers. Both alternatives offer limited recourse to competitive pricing.

Thisresource guide explains the complex meat laws in layman terms and clarifies the legal logistics of directmarketing livestock and poultry. Ultimately, this should lead to a more direct market chain from farmer toconsumer in New York and hence, more dollars circulating in local communities. Why are regulations for the processing and marketing of meat more complex than those for vegetablesand fruit?

Many of the acute human health problems posed by fresh fruit and vegetables are caused byunsanitary water and are not considered a critical threat in the US where we are blessed with potable water.

Health pathogens can multiply rapidly in animal products that are improperly handled. The United Statesacknowledged early on that poorly managed livestock and their products could pose a threat for human health. In , USDA Secretary Isaac Newton urged Congress to enact legislation providing for the quarantine ofimported animals.

On May 29, , President Chester Arthur signed the act establishing the Bureau of AnimalIndustry, which was the forerunner of Food Safety Inspection Service. This truly was the turning point for foodinspection because of public outrage at the unsanitary processing practices reported. Federal inspectors wereestablished in slaughterhouses for the first time because of the public outcry. The rapid growth of the interstate highway system and the development ofrefrigerated trucks allowed packinghouses to expand and to become more mechanized.

There was alsoexplosive growth in the poultry industry. The Bureau of Animal Industry evolved into the Food SafetyInspection Service FSIS , a public health agency within the U. This agencyoversees the processing, labeling, and packaging of commercial meat, poultry, and egg products. Congresspassed the Poultry Products Inspection Act in to keep pace with the rapidly expanding market for dressed,ready-to-cook poultry and processed poultry products.

Initially inspectors used sight, touch, and smell methods of inspection for meat products. Astechnology advanced, laboratory testing was adopted to ensure that products were maintained under properconditions and were free of disease pathogens. Under HACCP, the plant operator must identify all critical points along theprocessing and handling route where microbial and pathogenic problems could develop.

The operator must 5. The product is therefore not inspected by a state or federal inspector directly, as the job of theinspector under HAACP is to ensure the hazards identified, the process to test and the corrective measures areundertaken according to each plants own personalized plan.

Compliance Versus Circumventing The purpose of government regulations for the inspection of meat products are to 1 prevent the sale ofadulterated, contaminated, or otherwise unsafe livestock products, 2 insure the safety of consumers byestablishing minimum standards for the production, slaughter, processing, and marketing of these products, and3 create a system of licensing, inspection and labeling to trace a product back to its origin if a public healthproblem should arise.

An inadvertent side effect of increased regulation and validation is that smallerprocessors and farmers may be disproportionably disadvantaged due to economy of scales. This negativeimpact conflicts with the stated aim of our NY agricultural agencies to increase the sales of value-added farmproducts. However, close study of the meat statutes reveals some exemptions and alternatives that can benefitsmall farmers and processors marketing slaughter animals or meat products.

It is far better to have an excellentunderstanding of the meat regulations and to diligently study any changes in their interpretation rather than tofocus on circumventing them and risk trafficking in illegal or unsanitary products.

The New York livestockindustry needs to build strong communications with meat officials. There needs to be a better way to quicklyapprise officials, as even a small change in the interpretation of a law, can have significant implications forfarmers and processors.

Making sure our livestock farmers are knowledgeable about the current regulationsgoverning meat products and slaughter is a positive first step. How Regulations are Classified Livestock slaughter and meat processing regulations vary according to several factors.

The first factoris to determine what type of animal you are raising. You must decide if your animal is considered amenable,non-amenable, or poultry? The second factor is to decide where along the marketing chain from farm toconsumer you are planning to market your animal.

Are you marketing live animals, carcasses, or retail cuts? Are you marketing direct to the consumer or to a retailer or wholesaler? The third factor is to determine whattype of slaughter facility in your state is licensed to handle different kinds of sale.

What is a federally inspectedfacility as compared to a state inspected facility? How does a 5A custom plant differ from a custom plant?

Areyou marketing in state, out of state or are you exporting out of the country? The last factor is to considerwhether your animal needs to be raised, slaughtered, and processed under specialized restrictions to meet thereligious requirements of your consumer market. The following section is designed to help you determinewhich category under which your farm operation falls.

Once you determine your classifications, it is far easierto figure out which regulations apply. Are Your Animals Amenable, Non-amenable, or Poultry? First you need to determine how your livestock is classified. The regulations differ for amenable, non-amenable, and poultry species. The Federal Meat Inspection Act defines the kinds of animals that must beslaughtered and processed under the Food Safety and Inspection Service FSIS. In the world of meat processing, amenable indicates animalspecies that are specifically mentioned in the Federal Meat Inspection Act.

The listed amenable animals withinthe act include all cattle, sheep, goats, swine, equines, and ratites ostrich, emus, and rhea. These animals areconsidered amenable species and fall under the jurisdiction of the FSIS. Amenable Poultry listed under the Act include chickens, turkeys, ducks, geese, ratites, guineas, andsquabs. These poultry are listed specifically in the act. All of them fall under the jurisdiction of the FSIS.

However, the slaughter and processing regulations specified for them differ from those for the mammalsmentioned earlier. Animals that are not listed specifically in the Federal Meat Inspection Act are referred to as non-amenable species.

They are not required to be processed under the Food Safety and Inspection Service. Forthe most part, non-amenable species are animals that are traditionally used for game, and hence, are consideredmore difficult to regulate. They include mammals such as reindeer, elk, deer, antelope, water buffalo, bison,squirrel, opossum, raccoon, rabbits, nutria or muskrat, and non-aquatic reptiles such as land snakes.

Theseanimals are considered non-amenable even if you farm raise domesticated species of them. For example, farmraised White-tailed Deer or New Zealand rabbits are farm-raised game and a non-amenable species.

Althoughthey are not processed under the jurisdiction of FSIS, there are still plenty of regulations governing theirslaughter and processing. Non-Amenable poultry includes game birds such as pheasant and quail Aquaticreptiles turtles, alligator, water snakes, and frogs are considered game animals by the New York StateDepartment of Environmental Conservation.

The FDA considers these aquatic reptiles as Seafood and they aretherefore subject to US FDA Office of Seafood regulations. The National Marine Fisheries Service NMFS ofthe National Oceanic Atmospheric Administration of the Department of Commerce administers the voluntaryseafood inspection program. A Game Animal refers to an animal, the products of which are food, that is not classified as cattle,sheep, swine, goat horse, mule, or other equine, as defined by the Federal Meat Inspection Act, the Poultry andPoultry Products inspection Act or as fish.

Game animals are defined in section of the NYSEnvironmental Conservation law. Wild game includes game birds, big game and small game. Game birds aresubdivided into migratory game birds and upland game birds. To qualify as domestic game, captive bred game, farm raisedgame or non-native big game, the game must be held in private ownership on a licensed premise by whichthere is no means of escaping into the wild.

Captive bred North American big game mammals may include: Some wild game may be taken by lawful hunting including deer, bears, coyotes, and rabbit. Trapping ofgame is also permitted but deer and bear may NOT be trapped. Some wild species legally taken legally huntedor trapped within the designated season and legally possessed may by sold.

Skunk, bobcat, mink, raccoonand muskrat may be bought and sold alive, dead or in part during their respective open seasons. Migratory gamebirds and beaver, fisher, otter, bobcat, coyote, fox, raccoon, skunk, muskrat and mink shall be possessed,transported and disposed of only as permitted by regulation of the department.

The flesh of cottontail rabbits,varying hares, European hares, squirrels, bear and deer shall not be bought or sold, except as provided insection with respect to bear. For more information contact the New York State Department ofEnvironmental Conservation. Federal, State or Custom: Not all slaughterhouses are the same. It is important to know the different types of slaughterhousesoperating in the United States and the markets they are allowed to process for. Below is a list of theslaughterhouse categories.

Not all of these are available in New York. A USDA licensed slaughterhouse is a processing plant that has been granted a license for federal meatinspection. The current address is http: There are some conditions where meat is exempted from having to conformto all or part of this code. Some states hold theirUSDA licensed slaughterhouses to stricter regulations than what is outlined in the federal code. New Yorkgenerally follows the letter of the federal code.

Federal meat inspection means that a USDA Food Safety Inspection Service FSIS inspector at aUSDA licensed slaughterhouse must inspect the carcasses. Currently, the salary of this inspector is paid for byfederal tax dollars. The inspector must address all federal regulations outlined in the code.

Inspected meat from these slaughterhouses can be sold anywhere in theUS and exported and either sold or traded in international markets. State or local inspected custom slaughterhouses — these slaughterhouses are limited only to customslaughter and processing and are not to be confused with state licensed plants that undergo state inspection ofcarcasses for intrastate sales. Carcasses are not inspected under custom slaughter but thefacilities are. The USDA Food Safety Inspection Service has jurisdiction over all amenable red meat processingin the US but may opt to subcontract out inspection of custom facilities.

Local health departments are also involved because they must approve theslaughterhouse septic system prior to opening and will be responsible for testing any well water to validate it aspotable twice yearly. Some basic requirements of a custom slaughterhouse are 1 washable walls and floors forexample, painted concrete , 2 kill floor located in a separate area from processing, 3 drains equipped with aback-flush system, and 4 hot water capability of F for melting poultry fat.

Some custom slaughterhousesdo not apply to have an approved kill floor and are set up primarily to process white tail deer for NY hunters 5A Slaughterhouse facilities — These are specialized custom slaughterhouses that have applied forspecial NY permits.

Generally they have applied to slaughter non-amenable farm raised game species bison,farmed deer, rabbits, etc. They are permitted to slaughter these animals for producers for resale. Theslaughterhouse may also buy the meat from the farmer and market it themselves in a meat shop affiliated withthe slaughterhouse or sell the meat to a wholesaler or retail outlet under a C license. The meat can be soldwithin state or across state lines but must be sold directly to an end consumer or a restaurant, hotel, boardinghouse, caterer or similar retail business.

Both states must agree to the transaction and some states prefer not toin an effort to protect their own industries. For example, Pennsylvania does not permit farmed deer carcassesfrom NY to come into the state. If the meat is processed by mixing it with meat or fat from a conventional amenable livestock species or if the meat is cured using nitrate then further restrictions may apply.

Thecarcasses are not inspected. The facilities are inspected by state employees and tend to be held to a higherstandard that conventional custom plants. A blue print or schematic of the plant must be submitted andapproved prior to licensing. In the future, these plants may need HACCP plans documenting their handling ofproducts for resale. The live poultry markets in NYC are an example of 5A plants operating in thiscapacity. In NY it is generally accepted that a person may become an owner of the poultry by phoning in anorder for a specific type of bird.

However, if the slaughterhouse slaughterspoultry for a farmer for resale to restaurants or private end users, these birds must be slaughtered and processedseparately under the USDA exemption described in the later section on poultry. Other Types of Slaughter Houses Not Available in New York Talmadge-Aiken Meat Plants are federally inspected slaughterhouses where state employeesfollowing federal mandates do the inspections.

States on the east coast that contain Talmadge-Aiken meat plantsare Delaware 10 , Maryland 21 , Florida, Georgia, North Carolina and Virginia. Inspected meat from theseplants can be sold across state lines. New York has no Talmadge-Aiken plants. State licensed slaughterhouses have been granted state licenses for state inspection of carcasses.

Vermont, West Virginia, Ohio and now even Maine operate state licensed plants. New York does not operateany state licensed plants. These plants have been granted licenses for inspection similar to USDA plants. However, their inspectors are paid for by state tax dollars and inspect carcasses and facilities for compliancewith state rather than federal regulations. Inspected meat from these plants can be sold within state forintrastate commerce but not out-of-state interstate commerce.

Religious Exemptions Some cultures have very strict meat handling requirements. Halal requires that the animal must be humanely killed by an adult Muslim. However, some Muslimswill accept Kosher killed meats especially if Halal is unavailable and some will accept meat killed by aChristian slaughterman. A hand guard is permitted for safety. Muslims view any goat that has consumed any pork including lard or bloodmeal products to beunclean.

Customers who are Orthodox Jews require that livestock be Kosher killed. The animal is killed withoutstunning by a specially trained religious Orthodox Jew using a properly sharpened special knife with no handguard, who subsequently inspects the carcass and organs for defects. The sciatic nerve and various veins, fats and blood are prohibited for Kosher consumption and must beremoved. In most cases, rather than going through the difficult procedure of removing the sciatic nerve in thehindquarter, only the forequarter is marketed as Kosher and the hindquarter is sold through other marketingchannels.

The animal should either be killed on the ground allowable only for custom or on-farmslaughter , straddled, or walked onto a double rail for a religious kill because it is inhumane to hoist andshackled the animal by its hind legs while still alive. Information about the availability of double railslaughter systems for large commercial operations is available on the web athttp: A prototype of a double rail system for sheep and goats Although there are national certification programs for Kosher and Halal processed foods, there is nonational mandatory labeling and certification for Halal or Kosher meats.

The new law requires that consumers of food represented askosher in New York be provided with information identifying the person or organization certifying that food askosher.

The information must be provided by producers, processors, packers, distributors and retailersdistributing or offering for sale in New York food certified as kosher. They must file with the Department thename, address and phone number of the person or organization providing the kosher certification. Personscertifying non-prepackaged foods kosher must file with the Department a statement of their qualifications forcertifying food as kosher.

Food establishments and caterers who prepare kosher food on their premises mustcomplete, display at their place of business and file with the Department, a Kosher Certification Formprescribed by the Act. If you are involved in the kosher food industry as a producer, processor, packer,distributor or retailer of kosher food products, as a certifier of kosher food products, or as an operator of a foodestablishment who prepares kosher food, you may need to file product and certifying information with the NewYork State Department of Agriculture and Markets.

To do so, as of December 1, you may go towww. Theresponsibility for registering the person or organization who certifies a food as kosher and for filing informationabout products offered for sale as kosher depends on whether or not the food is in package form.

A food is inpackage form when it is not intended to be consumed at the point of manufacture and is packaged in advance ofsale in units suitable for retail sale.

If the food is in package form, the producer or distributor must register thename, address and phone number of the person who certified the food as kosher with the Department.

If thefood is not in package form, the person who manufactures, processes, packs or sells it must register the name,address and phone number of the kosher certifier with the Department. Examples of non-packaged food includenuts sold in bulk, repackaged potato salad from the deli, store baked breads and fresh meat. Kosher certifierswho certify non-packaged food must file with the Department a statement of their qualifications to providekosher certification.

The statement may include background, training, education, experience and any otherinformation that shows the kosher certifier's qualifications. Food establishments, restaurants and caterers thatprepare and sell food as kosher on their premises must file the name, address and phone number of the koshercertifier with the Department.

If any of theinformation filed with the Department changes, the person who filed it must notify the Department of thechanges immediately. The above requirements take effect January 9, Forms will be available online as ofDecember 1, at www. Filingsmust be done 30 days in advance of offering or distributing food as kosher in New York. Firms that utilize their own employees or personnel to certifyproduct need to have those employees complete General Information and Statement of Qualification.

Foodestablishments, food retailers, restaurants, caterers and food carts who sell food prepared on their premises orunder their control, which is represented as Halal, must post, at their business in a location readily visible byconsumers and file with the department, a Halal certification form.

Retail stores that sell both Halal and Non- Any advertisement for food or foodproducts representing the products as Halal shall identify the name of the person or entity certifying the productas Halal. You can file the information electronically by going to the Department websitewww. If you have questions on how to complete the forms or wish to submit the forms in print form andneed them sent to you please call the above number.

Certain African, Caribbean, and Oriental cultures prefer carcasses to be scalded or singed as part of theprocessing. A federally inspected slaughterhouse needs to include this step and describe how they will maintainfood safety in this process in the mandatory hazard analysis portion of their HACCP Hazard Analysis CriticalControl Point Plan.

These regulations are not consistent across the three different animalclassifications. Other chapters discuss the regulations for amenable livestock, amenable poultry, and non-amenable animals, respectively. A typical supply chain has a farmer selling his slaughter animals at a local auction where a regionallivestock dealer picks them up to sell to a distributor either directly or through a regional auction. Thedistributor could be a meat packer slaughterhouse that takes orders for carcasses from wholesale or retailbusinesses and then buys live animals and processes them to fill the orders or a wholesale business that buysanimals outright and then arranges their processing at a slaughterhouse of their choice.

The distributor thensells the carcasses or meat cuts to retail businesses that in turn serve the direct consumer. There are several opportunities for shortcuts along this chain. These shortcuts are notaccompanied by additional regulation other than needing to make sure amenable livestock are wearing officialUSDA identification. However, there is generally more labor and responsibility involved than just droppingyour animals off at an auction.

You need to contact buyers, accurately describe your animals, make sure theymeet the market demand, arrange transport and insure that you are paid. Even greater advantages are recognizedwhen a farmer sells their livestock directly to consumers, who then make slaughter arrangements.

Not only that, but the consumer often has a chance to visually evaluate the herd health and can easilytrace back any health problems that may arise.

A farmer can also evolve into a dealer or packer. If this occurs,then there are several licensing and bonding issues one should be aware of. These are discussed in section --Some farmers opt to build custom slaughterhouses on their property and expand their operation to include a liveanimal market. These are discussed in section A farmer may also decide to shorten the marketing chain by selling meat products. When selling meat, itis important to remember that the closer the market channel you sell to is to the actual consumer, the moreresponsibility you generally take on.

Regulations and licensing for amenable red meat differ depending onwhether you are operating as a wholesaler and selling carcasses or retail cuts to other wholesalers, retailbusinesses, and restaurants, or whether you are operating as a retailer and selling meat cuts direct to consumers.

In the case of poultry, there is an important exemption from federal inspection of the meat if you are selling These businesses are restaurants, hotels, boarding houses, caterers, and small stores thatuse the unadulterated poultry for meals prepared by the business for direct customers.

For example, a smallshop could purchase uninspected chicken carcasses from you if they are cooking it as rotisserie chicken forconsumption by their clients but not if they are buying it to resell as packaged raw meat. The regulations formarketing and processing live animals, carcasses, or retail cuts to consumers, wholesalers, or retail businessesdiffer substantially depending on how your livestock are classified.

Refer to chapters 2, 3, or 4 to determinewhich regulations apply to your specific circumstances. Intrastate or Interstate NOTE: In this section and the one following on Imports and Exports we address the movement of meatand meat products. Movement of live animals in interstate and international trade is beyond the scope of thisproject as states and countries have very rigid and specific requirements for live animal movement.

Pleaseconsult the New York State Department of Agriculture and Markets for information on moving live animals forinterstate and international trade. Intra-State refers to transactions within a single state. A sale made between a farmer in Owego, NY to acustomer in Ithaca, NY is an intra-state sale. Inter-State refers to transactions across state lines. This is trade between two states.

A sale madebetween a farmer in Whitehall, NY and a customer in Rutland, VT is an inter-state sale. The Food and Drug Administration FDA under the Federal Food, Drug and Cosmetic Act, hasauthority over food in interstate commerce unless regulated by the USDA Food Safety and Inspection Service FSIS. The Federal Meat Inspection Act permits states to have a cooperative agreement with USDA FSIS,whereby states have a mandatory meat inspection program equal the federal standards.

The federal law limitsstate inspected amenable animals to intrastate commerce. However, this limitation is currently being challenged. Non-amenable state inspected meat is eligible for sales in all states, including states with stateinspection programs.

Chapter Twelve: Marketing Meat, Poultry, Eggs and Dairy Products | Direct Farm Marketer's Forum

Just because it is eligible for sale does not guarantee that it is legal for sale. State or localhealth codes may prohibit the sale of non-inspected non-amenable meat. It is recommended thatthe producer call the State Department of Agriculture and the State Department of Fish and Game or NaturalResources to see what products are allowed to come into the state and the inspection required to do so. Import is the act of bringing into a country a commodity from another country or place for sale orexchange.

Export is the act of sending a commodity to another country or place for sale or exchange. For ourpurpose, import and export will be defined as a transaction between two countries as opposed to two places. The destination of the end product may in some cases determine the inspections required.

The Federal Meat Inspection Act FMIA requires that countries exporting meat products to the UnitedStates impose inspection requirements that are equivalent to U. All meat productsimported into the United States must bear the country of origin on the labeling of the original container in whichthey are shipped. If an imported meat product is intended to be sold intact, then it must remain in its original packaging with the country of origin and foreign establishment number on the label to the point of consumer purchase.

For example,ham salad made from imported Danish ham does not need to bear a label identifying the country of origin of theham. The labeling requirements for the resultant product are the same as for domestic product. Additional requirements may be made on the importation of various products into the United States.

Forexample, meat from cattle being imported from Canada into the United States must be tested for BSE. Beefcattle over the age of thirty months are not allowed. For the specifics of import and export you must consult theNew York State Department of Agriculture and Markets and the USDA. Inspection Determination Who OwnsFlow Chart for Amenable Meat animal? In State Retail or Out of State For personal Wholesale?

Why a Tiered System? Food and Drug Administration FDA Under the Federal Food, Drug and Cosmetic Act, the Food and Drug Administration FDA protectsconsumers against impure, unsafe and fraudulently labeled food.

The regulations require FDAinspection of the facilities and processes involved in slaughtering and processing of food. FDA inspections areusually done once a year. According then to the FDA the source and process, not the animal itself, must be inspected and approved.

Themost common approved sources include a licensed food establishment, a federally inspected meat plant or astate-inspected meat plant. The FDA does not allow the use of nitrite or nitrates in food products, therefore allmeat food products must be manufactured under USDA FSIS inspection.

The FDA is also responsible for medicines, cosmetics, animal feed and drugs for pets and farm animals. The FDA ensures that products are labeled truthfully with the information that people need to use themproperly. If a company is found violating any of the laws that FDA enforces, FDA can encourage the firm tovoluntarily correct the problem or to recall the product from the market.

A recall is generally the fastest andmost effective way to protect the public from an unsafe product. FSIS inspectors examine each animal before and after slaughter for visible defects that canaffect safety and quality of meat and poultry products.

FSIS regulations require ante-mortem and post-morteminspections of each animal AND daily inspection of processing facilities by FSIS inspectors. The Federal Meat and Inspection Act defines specifically the kinds of animals that must be slaughteredand processed under FSIS inspection.

The Agricultural Marketing Act of Voluntary Reimbursable Inspection allows FSIS to inspectexotic animals under a voluntary inspection program. The producer must pay for the voluntary FSIS inspection. FSIS regulations governing the slaughter and processing of exotic animals do not require HAACP or riskassessment.

At present FSIS is considering the addition of bison, elk, deer and other species to the list ofanimals requiring USDA inspection. A provision of the Federal Meat and Inspection Act permits states to have a cooperative agreement withUSDA FSIS, where by states may have mandatory inspection programs equal that of the federal standards.

New York does not have aUSDA FSIS equivalent program. Therefore, while all New York slaughterhouses are New York Stateinspected there are no New York Slaughterhouses that are USDA equivalents.

OTHER AGENCIES The Environmental Protection Agency EPA licenses all pesticide products distributed in the UnitedStates and sets standards on the amount of pesticides that may remain on food. EPA is also responsible for The National Marine Fisheries Services NMFS conducts a voluntary seafood inspection and gradingprogram that checks mainly for quality.

Quality and safety standards vary widely from country to country and inspection ofprocessing is a challenge because much of it takes place at sea. Mandatory regulation of seafood processing isunder FDA and applies to exporters, all foreign processors that export to the United States and importers.

The AgriculturalMarketing Service, Grain Inspection, Packers and Stockyards Administration, and Animal and Plant HealthInspection Service of the USDA. Food safety issues are generally supported by the Center for Disease Control and Prevention of theDepartment of Health and Human Services.

The CDC engages in surveillance and investigation of illnessesassociated with food consumption in support of the USDA and FDA regulatory missions. The Federal TradeCommission, through regulations of food advertising, plays an indirect role in food safety regulations. Transportation of AnimalsHumane Transport The following suggestion will help you move your animals in a low stress manner. Animals that are overstressed will tend to have more health problems, greater shrinkage, less desirable meat characteristics, and aremore dangerous when handled.

Life for the handler and the animal is much better when using low stresspractices. Respect livestock - don't fear them! Animals sense their surroundings differently than humans. Their vision is in black and white, not incolor. As a result animals move more readily from dark areas into light, but avoid layouts that make them lookdirectly into the sun.

Lighting should be even and diffused. Bright spots and shadows tend to make animalsmore skittish, especially near crowding or loading areas. Wear clothing that will not cause handler to stand out,again this may cause the animal to balk or turn away. Keep loud noise to a minimum and avoid quick movements or loud noises. Most animals will respond toroutine; be calm and deliberate.

Be patient; never prod an animal when it has nowhere to go. Move slowly anddeliberately around livestock; gently touch animals rather than shoving or bumping them. Flight zone — See Diagram 1 Animals have a flight zone. A flight zone is the area where an animal willbegin to move away from the person or thing that is approaching. Animals also have a point of balance fromwhich point you can direct the movement of an animal forward or backward.

This point is located at theshoulder of the animal. If you move toward an animal from the front it will move to the rear. If you cometoward an animal form the rear and side it will move forward and in a circular motion around you.

Whenmoving animals always try to move them in small groups. In place ofelectric prods use sticks with cloth on them or you can purchase large plastic paddles that help move theanimals more smoothly.

Use the stick as an extension of your arm to direct the animal. These will cause the animal to balk orturn back away from the direction of travel. Always have an escape route when working with an animal in close quarters. Alleys and chutes should be wide enough to allow animals to pass, but not wide enough to allow them toturn around. Solid wall chutes, instead of fencing, will lower the number of animals that balk in the chute. Animals move better if directed through a circular solid walled chute.

Handling equipment can speed uplivestock confinement work operations, reduce time and labor requirements, cut costs, and decrease the risk ofinjury. When transporting animals avoid cold and wet conditions whenever possible. These are stressful on theanimal and can cause illness. Use slow starts when accelerating and avoid sudden stops when braking. Allowextra time then what it would normally take to compensate for the slower movement of a trailer.

It may alsotake more distance to stop a trailer hauling livestock. For more information on animal transport contact the USDA Agricultural Marketing ServiceTransportation Program. How Many Animals Can I Load on a Trailer? Shrinkage Shrinkage or shrink refers to the weight loss that occurs in live weight from the time the animal isgathered for transport until it is slaughtered.

Livestock coming off lush pastures will show live weight lossesshortly after being taken off feed because the feed passes through them faster than dried forages and grains do. If animals are deprived of feed for 6 or more hours not only live weight but carcass weight starts to decreaseand dressing percentage DP will also start to drop. Carcass weight loss in young goats is about 2.

Slaughtering, Cutting, and ProcessingSlaughtering, Cutting, and Processing of Amenable Meats: Selling amenable red meat wholesale, retail and direct to the consumer In NY all red meat for resale from amenable species must be slaughtered at a USDA licensed facilityand the carcass inspected by a FSIS inspector.

This is not true throughout the entire Northeast US. Forexample, in Maine, Vermont and West Virginia it can be slaughtered in a state licensed facility and the carcassstate inspected if sold within state. In Delaware, Maryland and Virginia it may be slaughtered at a Talmadge-Aiken plant.

At the USDA slaughterhouse the animal: Because the returns from slaughtering small ruminants are generally less than for doing cattle or hogs, some slaughterhouses no longer apply for federal inspection for small ruminants.

Thus, you could not take a lamb to them for federal inspection. In general the large rails used for doing large animals will also work for small ruminants.

However, a slaughterhouse that is only set up to handle small ruminants may have its rails set too low to be suitable for hogs and cattle. During deer season, carcasses brought in by hunters must be kept separate from USDA inspected domestic meat.

Depending on the size of the slaughterhouse and the FSIS inspector, this can mean that the inspector may ask plants that process meat for hunters to accept no domestic livestock during deer season or to store deer carcasses in separate coolers or even simply on different rails than domestic carcasses.

Amenable species may be field harvested under extreme conditions with prior authority by USDA officials. This is not a common practice and frowned upon for amenable species. Animal species that are difficult to load, transport and handle can be killed directly on-farm. This is typically limited to buffalo, bison and cervids and not amenable species.

The dead animal must be transported to a USDA or 5A slaughterhouse within 2 hours for processing and be accompanied by a Veterinarian signed certificate of good health. The customer can request various organ meats at a USDA slaughterhouse. Typically these organs would include the heart, liver, tongue and kidneys.

Tripe and lungs are more difficult to acquire. Animal parts such as brains and spinal cords, which may harbor any TSE prions, are not available for consumption and must be properly disposed of. Generally organs and part not fit for consumption are marked or dyed in a non- edible substance and taken off the facility.

Poultry Rations and Feeding Methods | Manitoba Agriculture | Province of Manitoba

Currently there is no official offal disposal requirements for the different amenable species, although it is recommended that parts which may have the potential for any type of TSE BSE, scrapie or CWD contamination be sent to public landfills and buried. Composting is an accepted method of disposal but there is debate within the industry as to whether this practice should continue.

Rendering companies may collect offal and cook and separate the components for later use in animal feeds. Amenable meat must be processed either at a USDA slaughterhouse or in a state certified kitchen also known as a 20C-licensed facility.

This is not the same as a certified kitchen for baking, or for processing jams and jellies. Processing includes even just repackaging of the meat into smaller sized packages. Keep in mind that if the meat is processed in a state certified kitchen it cannot be sold out of state.

USDA inspected fresh meat for resale must be transported at temperatures below 40 F. It must either be stored in a separate freezer from non-inspected meat or stored in a separate area of the freezer. For example, it must be stored in the top shelves of an upright freezer above any non-inspected meat or in a separate area of a chest freezer. It permits the owner of an animal to slaughter their livestock on-farm orthrough a custom slaughterhouse without having the carcasses inspected if the meat and byproducts are to beused for home consumption by the owner, their immediate family, non-paying guests and employees.

In NY it is assumed that a person owns an animal when they purchase it. As inseveral other states, state officials interpret the exemption to allow a farmer to pre-sell portions of the liveanimal.

Thus, a customer can purchase a lamb, goat, steer or hog from a farm or live animal market, takeownership of it, and arrange for slaughter at a custom slaughterhouse. The farm owner or customslaughterhouse operator may also act as an agent for the owner and arrange transportation of the animals orcarcasses.

In cases where NY custom slaughterhouses have allowed customers to handle the slaughtercompletely and customers have wanted to slaughter outside, a sanitary 3-sided shed with a drain to an approvedsanitary system has been required by inspectors. Substantial liability insurance may also be advised. Offaldisposal is a major consideration. However, on-site composting of offal is legal in NY if done properly with ahigh carbon substrate such as wood shavings or straw and without chance of contamination of water sources.

For more information on composting contact your local Cornell Cooperative Extension office. It is important to note that some states take a strict interpretation of the custom exemption and considerthe owner of the animal to only be the person who actually raised it. There are some lingering questions that need to be answered which answers are needed for: Can yousell halves and quarters of an animal?

Do you have to sell it by the head or live weight what kind of scalerequired if so or can you sell it by hanging carcass weight? Can you advertise freezer lamb for sale orslaughter goats for sale or? Who has to pay the processing fees? Who has to pick up the meat? What offal must be specially handled? Can you let religious slaughtererhelp with the actual kill?

Decision Flow Chart for Amenable Livestock SlaughterAsk yourself the question in the bold type and then follow the appropriate Yes or Noresponse arrows to determine where your amenable livestock can be slaughtered andprocessed. You must read the criteria on the cited page before you can determinewhether your operation fits the circumstances.

Do you sell your slaughter animals yes Is the animal to be consumed only by thedirectly to the consumer either by phone yes consumer, their immediate family andor in person prior to slaughter? Slaughtering, Cutting, and Processing of Non-Amenable Meats Most non-amenable meat and meat products are derived from farmed game.

Often these animals posechallenges to the producer not experienced by domesticated livestock. Handling, loading and transporting gameanimals represents a true challenge to the game farmer. To help these producers the USDA has allowed for on-farm harvesting. In this situation a game farm must have a separate area in which to present the live animal s toa licensed veterinarian or USDA inspector, before being dispatched on the property.

The animal is then bled outand transported to a USDA or NYSDAM licensed 5-A facility. The animal must be accompanied by aveterinarian signed Certificate of Health and must arrive to the designated destination within two hours. Chronic Wasting Disease CWD have required that specific cutting techniques be employed. For deerand elk, hand boning is required and parts that may pose a human health risk such as the brain, spinal cord andspecified lymph nodes must not be severed, must not appear in any end product and must be disposed of in amunicipal landfill.

According to NYSDAM CWD monitoring program all slaughterhouses custom, 5-A, orUSDA operating in NYS and processing deer must have an offal disposal plan on record with NYSDAM.

Fresh or fresh-frozen whole meats, ground meat with no additives and sausage with no nitrite cures maybe cut and packaged in a NYSDAM 5-A facility. Value added game meats cured with a nitrate and without the addition ofan amenable meat, meat product or fat can only be processed in a USDA facility.

Value added game productsfrom a USDA facility would bear the USDA mark of inspection for a non-amenable meat product. This mark iscircular as opposed to triangular. All non-amenable meat must be clearly labeled and if the addition of amenable meat and otheringredients are added, this must also be noted. Instead, a USDA slaughterhouse can request a state license to slaughter and process domestic cervid.

Thelivestock owner must then pay a certified USDA FSIS inspector out-of-pocket to inspect the carcasses for saleto restaurants or other retail and wholesale outlets. The slaughterhouse must have a holding pen where the federal inspector can observe the animal withoutapproaching it.

The top rail height should be 6 ft. The animal can also be slaughtered on farm field harvest and then transported to theslaughterhouse within 2 hours for processing. The meat can be sold out-of-state with approval of the importingstate.

Rabbits — There is no USDA inspection for domesticated meat rabbits. They are also considered a non-amenable species. The producer must pay for the carcass inspections out of their own pocket if the meat is forresale to wholesalers.

They can be slaughtered at a 5A slaughterhouse if the whole carcass is being sold to endconsumers or retail outlets. As of May , these carcasses can be broken down into whole muscle meats at a5-A or C establishment. They can be slaughtered at a custom slaughterhouse or on-farm if the consumerpurchases them as live animals prior to slaughter. Decision Flow Chart for NON-Amenable Livestock SlaughterAsk yourself the question in the bold type and then follow the appropriate Yes or Noresponse arrows to determine where your non-amenable livestock can be slaughteredand processed.

Will any of the animal or product yes You must contact the statederived from its meat be delivered department of agriculture of theout of New York State? Slaughtering, Cutting and Processing of Poultry Poultry — probably one of the most important exemptions to the federal code for small farmers is thepoultry exemption.

The businessneeds to be one that is going to use the unadulterated poultry for meals prepared by the business for directcustomers. There is a limit to how much poultry a farm can sell this way. Under NY state regulations, a turkey counts as four chickens. The exempted birds can be slaughteredon farm depending on local and state zoning regulations or at a slaughterhouse. The poultry is for the private use of the: The poultry is healthy when slaughtered;4.

The poultry is slaughtered and processed under sanitary conditions and practices that result in poultryproducts that are sound and fit for human food;5. The exempt poultry is not sold or donated for use as human food; and6. The shipping containers bear: Instead of the Federal law , a State law may be cited when the inspection of the slaughter and processing of poultry is exempted under the authority of a State law and the operations are reviewed by a State Agency.

There is no limit to the total amount of poultry that owners of poultry may slaughter and process for theirprivate use. If any of the six criteria are not met, the poultry is not eligible to be processed under this exemption.

A custom slaughterer provides a service to a customer and does not engage in the business ofbuying or selling poultry products capable of use as human food. A custom slaughter business may slaughter or process an unlimited number of poultry when the poultry isdelivered by the owner and the following five criteria are met: The custom slaughterer does not engage in the business of buying or selling poultry products capable for useas human food;2.

The poultry is healthy when slaughtered;3. The slaughter and processing at the custom slaughter facility is conducted in accordance with sanitarystandards, practices, and procedures that produce poultry products that are sound, clean, and fit for human food not adulterated ;4. Instead of the Federal law , a State law may be cited when the inspection of the slaughter and processing of poultry is exempted under the authority of a State law, and the operations are reviewed by a State Agency.

Custom Slaughter Exemption Notes: For example, a custom slaughterer may sell live poultry to a person and then custom slaughter the bird. However, a person who custom slaughters poultry may not buy or sell poultry products used for human food.

Agricultural Marketing Resource Center | Agricultural Marketing Resource Center

Also, carcasses or parts of ostrich or poultry not slaughtered at the red meat establishment may be delivered by the owner for custom A person may slaughter and process on his or her premises poultry that he or sheraised and they may distribute such poultry without mandatory inspection when the following four criteria aremet: The poultry grower slaughters no more that 1, healthy birds of his or her own raising in a calendar year for distribution as human food; 2.

The poultry grower does not engage in buying or selling poultry product other than those producedfrom poultry raised on his or her own farm; 3. The slaughter and processing are conducted under sanitary standards, practices, and procedures that produce poultry products that are sound, clean, and fit for human food not adulterated ; 4.

The producer keeps records necessary for the effective enforcement of the Act, and 5. The poultry products do not move in commerce. A business may slaughter and process poultry under this exemption when the following criteria are met. The poultry products produced under the PGOP Exemption are distributed solely by the manufacturer andonly within the State or Territory or the District of Columbia in which the poultry product is produced;4.

The processing is limited to preparation of poultry products for distribution directly to: The shipping containers, when distributed in intrastate commerce, instead of all the required features of alabel for inspected product bear: State law, rather than Federal law, may be cited when product is produced in accordance with requirements of aState exemption.

The poultry are healthy when slaughtered;5. The shipping containers, when distributed in intrastate commerce instead of the required features of a labelof inspected product bear: In this situation, the grower is not required to request an exemption from the Administrator of FSIS. Small Enterprise ExemptionA business that qualifies for the Small Enterprise Exemption may be: Under this exemption, a business may slaughter, dress, and cut up poultry for distribution as human food whenthe following criteria are met.

Processing of inspected or exempt poultry product is limited to the cutting up of carcasses;2. The business slaughters and dresses or cuts up no more than 20, birds in a calendar year under theexemption;3. The facility operates and is maintained in a manner that prevents the creation of unsanitary conditions andensures that the product is not adulterated;4. The exempted product is not distributed in interstate commerce; instead, its distribution is limited to premiseswithin the District of Columbia or the State or Territory in which the poultry product is produced; and6.

The product is not misbranded. Small Enterprise Exemption Notes: A small enterprise is not required to have slaughtered the poultry it cuts up under a Small Enterprise Exemption. The small enterprise may purchase Federal or State inspected and passed poultry for its cut up operation fromexempt businesses that are allowed to sell to a small enterprise. A business may slaughter or cut up poultry under the Small Enterprise Exemption for sale to: A small enterprise is not prohibited from selling live poultry to a customer and then slaughtering, dressing, andcutting up the poultry for the customer.

A small enterprise may not cut up and distribute poultry products produced under the Small EnterpriseExemption to a business operating under the following exemptions: Retail Dealer Exemption, or Retail Store exemptions. The Act provides for several types of retail exemptions: The type of poultry slaughter and processing operations abusiness, conducts determines which retail exemption under which the business may produce poultry.

Abusiness is qualified to operate under a retail exemption when the following criteria are met. A PGOP cannot sell their products to retailers — only to household consumers, boarding houses, hotelsand restaurants];4. The business does not custom slaughter poultry delivered by the owner;5. The retail business does not prepare exempt products that the business sells to: The business may custom process poultry delivered by the owner provided that the poultry is from anacceptable source, Federal or State inspected and passed, or exempt poultry ;8.

The facility operates and is maintained in a manner that prevents the creation of unsanitary conditions andensures that the product is not adulterated. Operations of types traditionally and usually conducted at retail stores are conducted in the store and include: No canning operation is conducted in the retail store; Product sold in commerce is not misbranded; Sales of poultry and poultry products are in normal retail quantities or served to consumers at the retail store normal retail quantities are 75 pounds or less to household consumers and pounds or less to hotels,restaurants, and similar institutions ; and Sales to hotels, restaurants, and similar institutions do not exceed either one of two limits: The calendar year dollar limit for retail stores set by the Administrator of FSIS;Retail Store Exemption Notes: When a retail store that slaughters poultry takes orders for dressed poultry before the arrival of the customer,and also slaughters several birds at one time for various customers that have requested them, the birds must beidentified throughout the process so that processed bird that the customer receives is the same live birds selectedfor or by the customer.

FSIS District Office Contact InformationAlbany, NY Washington Ave. Extension Albany, NY Phone: Figure 1 Decision Flow Chart for Poultry ExemptionsAsk yourself the question in the bold type and then follow the appropriate Yes or Noresponse arrows to determine whether your poultry slaughter or processing operationmay qualify for an exemption. You must read the criteria on the cited page before youcan determine whether your operation qualifies for the exemption.

Do you slaughter or process poultry Inspection requirements offor sale as human food? No Y Yes Do you raise, slaughter, and processPersonal Use for sale as human food no more Custom SlaughterExemption — than 1, poultry in a calendarSee page 2 year? Retail Exemption — See page 8 NoAre you a business that raises, Yslaughters, and dresses poultry orpurchases dressed poultry that youdistributed as carcasses or parts?

Contact the FSIS District Office. Packaging Options Proper wrapping and rapid freezing contribute to a longer lasting quality product. The goal is to preventmoisture loss from the meat freezer burn and keep air out. Packaging options for meat cuts include: Any facility in NewYork that is using reduced oxygen packaging must have a HACCP plan in place for this activity.

The CutsIt is imperative when trying to sell cuts to a greater extent retail cuts as opposed to wholesale cuts that bothyou and your customer are in complete understanding of the product. As a salesperson you must be able to identify the cuts and makerecommendations on how to cook them.

Grass fed meats tend to be lean. Proper cooking techniques must beused to ensure tenderness. When in doubt, cook grass-fed meats low, slow and moist; never allowing them todry out. The meat should be cooked quicklyover a very high heat, then removed and allowed to rest.

Basting or barding should be practiced when dry roasting. Less tendercuts are an excellent alternative in soups, stews, casseroles and stir-frys where they can be braised, stewed orsauted to maintain tenderness. Try using broth, wine, fruit or vegetable juice or spring water with a crock-pot,Dutch oven or covered casserole.

Industry Cutting Charts Thepounds of meat you should get from an animal will be dependent upon the dressing percentage and the carcasscutting yields. A handy formula has been developed to help: Generally the carcassweight is taken immediately after skinning and evisceration and is commonly known as the hot hanging weight. There are a number of factors that will affect the percentage including how much the animal has eaten before itis weighed, how much mud or fiber is on the animal.

These factors negatively correlate to the dressingpercentage, by reducing the dressing percentage. The amount of fat and muscling will positively impactdressing percentage, the heavier or fatter an animal, the higher the dressing percentage. The dressing percentagecan be calculated as such: Youcould expect a pound steer to result in a pound hanging carcass or a pound market hog to producea pound carcass x. The carcass cutting yield is the percentage of the carcass that actually ends up as meat.

The carcasscutting yield is calculated by: Cutting yields can vary significantlydepending upon cutting specifications; cuts that are bone-in or boneless, will produce very different cuttingyields. If the animal is excessively fat, then the cutting yield will be lower because the fat is removed anddiscarded. A more muscular animal will have a higher cutting yield. Aging, leaving the carcass to hang for anextended period of time will also impact cutting yields as the carcass tends to shrink during the process.

Yield grades can help can help predict cutting yields. A yield grade measures the amount of boneless,trimmed retail cut from various parts of the carcass: The higher theyield grade the higher the carcass cutting yield percentage. A lower yield grade indicates a higher cutting yield.

To employ the help of a yield grade to determine the amount of saleable meat lets consider the followingexample. A yield grade 2 on a pound carcass would indicate saleable meat of If more cuts were left bone-in, then the actual carcass cutting yield would be higher than A pound steer will produce a pound carcass.

From this pound beef carcass you can expect around the following: Youcould also expect pounds in retail cuts at a yield grade 3 These figures provide only anapproximation to use as a guide. You should keep good records of dressing percentages and carcass yields tohelp you in your farm management and decision making process. Value Added ProductsFDA and Nitrate Usage Manufacturers add preservatives mostly to prevent spoilage during the time it takes to transport foodsover long distances to stores.

Without such preservatives, food safety problems would get out of hand. Preservatives serve as either antimicrobials or antioxidants—or both. As antimicrobials, they prevent thegrowth of molds, yeasts and bacteria. As antioxidants, they keep foods from becoming rancid, browning, ordeveloping black spots.

Rancid foods may not make you sick, but they smell and taste bad. Antioxidantssuppress the reaction that occurs when foods combine with oxygen in the presence of light, heat, and somemetals.

Antioxidants also minimize the damage to some essential amino acids—the building blocks ofproteins—and the loss of some vitamins. Many preservatives are regulated under the food additives amendment, added to the Federal Food, Drug,and Cosmetic Act in The amendment strengthened the law to ensure the safety of all new ingredients thatmanufacturers add to foods. Under these rules, a food manufacturer must get FDA approval before using a newpreservative, or before using a previously approved preservative in a new way or in a different amount.

Foodlaw says preservatives must be listed by their common or usual names on ingredient labels of all foods thatcontain them. Preservatives may not be used to deceive a consumer by changing the food to make it appear other thanit is. For example, preservatives that contain sulfites are prohibited on meats because they restore the red color,giving meat a false appearance of freshness.

The food additive regulations require the preservative to be of foodgrade and be prepared and handled as a food ingredient. Regulations about the use of nitrites demonstrate the scrutiny given to the use of additives. Nitrites, usedin combination with salt, serve as antimicrobials in meat to inhibit the growth of bacterial spores that causebotulism, a deadly food-borne illness.

Nitrites are also used as preservatives and for flavoring and fixing colorin a number of red meat, poultry, and fish products. Since the original approvals were granted for specific uses of sodium nitrite, safety concerns havearisen.

Nitrite salts can react with certain amines derivatives of ammonia in food to produce nitrosamines,many of which are known to cause cancer. In addition, other antioxidants, such as sodium ascorbate or sodium erythorbate, may be added to inhibit theformation of nitrosamines. Sausages, Smoked Meats and Dried MeatsFresh Sausages A fresh sausage is lean ground meat combined with fat or lard or other binding agent and seasoningssuch as herbs and spices.

Fresh sausage can be packed in bulk, formed into patties, or put into a casing and soldas links. Fresh sausage must be kept under refrigeration and cooked before being eaten. Cooked Smoked Sausages Cooked smoked sausages include products such as hotdogs and bologna. It is advised to keep theseproducts under refrigeration and to thoroughly heat before being eaten.

Fermented Sausages Fermented Sausages are a class of chopped or ground meat products that, as a result of microbialfermentation of a sugar have reached a PH of 5.

These products are typically cured but are not necessarily cooked or smoked. Semi-dry sausagessuch as summer sausage, thuringer, cervelat, and landjaegar have a higher moisture content and should berefrigerated.

They are generally cooked or smoked prior to sale or consumption. Dry sausages such as pepperonior salami are generally shelf stable and may be consumed without additional heating.

Below is a partial list of fermented sausages: A spicy Italian-style sausage that originated in the US. Beef case Italian-style salami Blockwurst: This is a general class of semi-dry sausages, generally swiss style, and includes Farmstyle, summer sausage , Goettinger, Goteborg, Holsteiner, Landjaegar, and Thuringer. This is a dry sausage historically prepared with wild game. An Italian Salami highly seasoned with hot peppers.

This salami is not fermented or acidified, but rather cooked. A rough chopped, highly seasoned, dry sausage. This is primarily pork product that is not smoked, originating from Genoa, Italy. This German style salami is heavily smoked, traditionally stuffed into calf bladders andcorded with twine. Regional differences result from the seasonings, stuffings and cording designs. Dry garlic-seasoned sausage of Swiss origin.

Lola is roughly one pound, and Lolita istwo and a half pounds. This salami has higher fat content and incorporates brandy into the recipe. This sausage has an intricate cording pattern. This is a French style using pork and pork fat seasoned with garlic. Made with beef, pork and bacon. This class of sausage must be treated and certified Trichina Free.

Generally it is not smokedor cooked. There are hundreds of types of salamis, usually made from pork and seasoned with garlic. Extenders and binders are permitted, and the product may or may not be cooked. A fermented sausage stuffed into hog casings with a wrinkled appearance. A dry sausage of Turkish origin. A farmer-style Cervelat, produced in the cooler months for summer eating.

A dry sausage containing pork and veal chunks, heavily seasoned with garlic,cooked and air-dried. Smoked Meats and Sausages Smoking adds desirable color, flavor and aroma to fresh or fermented meats. Smoking may also amethod of preserving meat but it should not be the only method employed, as any disruption to the smokedsurface will destroy the preservation.

Approved woods for smoking include hickory, oak, apple cherry andother fruitwoods , mesquite, redwood and even corncobs. Liquid smoke may be substituted for the actualsmoking process. Products may be hot smoked or cold smoked. Products are cooked during the early stages of ahot-smoke process. Smoked meatsshould be kept refrigerated and thoroughly cooked before being consumed.

Jerky and Dried Meat Jerky has been with us for hundreds of years. Native Americans combined jerky with animal fat tocreate Pemmican, a product know for it high energy qualities. Early European explorers prepared dried meatssuch as Charqui or Xarque. Biltong, an African version, was often produced using ostrich meat. Many of theseearly versions used salts and seasonings as rubs. Ingeneral, jerky is prepared using lean muscle meats, cut with the grain of the muscle fiber. All visible fat must beremoved to prevent rancidity.

Jerky has a very low moisture level and may be cured, non-cured, smoked, non-smoked, rubbed or marinated. Jerky can be made from amenable or non-amenable meat or poultry.

Kippered meats are similar to jerky but are allowed to have a higher moisture to protein level. Kipperedmeats are not shelf stable, and may need further heat processing and vacume packaging to retain productintegrity.

Snack sticks are generally made with shredded or ground meat, seasonings, and a cure. The mixture isstuffed into small diameter casings and hot smoked cooked and dried. Because they may contain fat, theyrequire antioxidants to control rancidity and vacume packaging to limit oxygen exposure. Their tangy taste isusually attributed to lactic acid or other organic acids to help prolong shelf life.

Recipe Development and Considerations Developing a great recipe takes time. Different ingredients, different fermentation and drying techniquesall add to the uniqueness of the end product.

Spices, seasonings and other ingredients add additional interest.

Ithelps to understand the sausage process when looking to experiment. The usual procedure in the making of a sausage is to grind the various meats coarsely and then add therest of the ingredients, mixing thoroughly. Generally the other ingredients spices and seasonings are first madeinto a slurry using a small amount of water before being mixed into the ground meat. The product is thenground again to the desired consistency.

Small batches up to 25 pounds are recommended so the cure andseasoning can be more evenly distributed. It is not necessary to stuff fresh sausage meat. It can be left in bulk form or made into patties. Mostsausage, however, is made by placing the ground ingredients in some type of forming device to give them shapeand hold them together for thermal processing. The casing materials may be natural or manufactured. Naturalcasings are the gastrointestinal tracts of cattle, sheep and hogs.

They are digestible and are very permeable tomoisture and smoke. Fibrous casings are more suitable for summer sausage and similar products because oftheir greater strength and the variety of sizes available. They are permeable to smoke and moisture and caneasily be removed from the finished product.

Collagen casings contain the attributes of both natural and fibrouscasings. They have been developed primarily for use in products such as fresh pork sausage and pepperonisticks.

They are uniform in size, relatively strong and easy to handle. These casings also are used for themanufacture of dry sausages, because they are permeable and will shrink. For products that are water-cookedplastic casings impermeable to water are used.

The success or failure of a value added meat product may be dependent upon the selection andcombination of spices and seasonings used. Typical beef spices include: Spices that complimentlamb include: Pork isoften seasoned with: Dried fruits such as cranberries, apples apricots andtomatoes can also be considered. Various chilies, onions and peppers can also add distinct flavors. Combinations of spices, seasoning and additions provide unique interest and lend to consumer appeal. Product HandlingTemperature and the Cold Chain Meat, meat by-products and meat food products must by transported in an enclosed vehicle in such amanner to assure delivery and wholesomeness of those products while maintaining product integrity.

Frozenproducts must remain frozen and all other meat and meat products must not rise above forty degrees Fahrenheitunless the product is temperature insensitive because it is manufactured, processed or packaged in such a way toprevent adulteration or unwholesomeness.

Jerky for example with a moisture level less than. Sampling and Slicing Sampling and slicing of meat by-product and meat food products is at the discretion of County HealthDepartments. Some departments require a food certification to carry out slicing of product for sampling. Somewill require the product be sliced in a licensed commercial kitchen others will require the product to be slicedon site.

Product that will be sampled must be USDA certified or be prepared in a state licensed commercialkitchen 5-A or c facility. Food Safety and Handling There are four components to safe food handling. First clean your hands with warm water and soap. Wash cutting boards, dishes, countertops and utensils with hot soapy water.

Keep your work area clean. Second, do not cross contaminate. Keep raw meat away from prepared products. Do not place cooked food on aplate or dish that previously held raw meat, poultry or eggs unless it was washed with hot, soapy water.

Third,keep products at their safe temperatures. This means keeping perishable food refrigerated. It also meanscooking food to their proper degree of doneness. Food is safely cooked when it reaches a high enough internaltemperature to kill the harmful bacteria that cause food-borne illness for red meat the internal temperatureshould rise to degrees Fahrenheit, and degrees Fahrenheit for poultry.

Use a food thermometer tomeasure the internal temperature of cooked foods at the thickest point. Sauces, gravies, and even leftoversshould be reheated to degrees. If using a microwave for reheating, the food should be stirred to make surethere are no cold spots. Finally, food should be refrigerated promptly. Meat should be frozen or refrigerated assoon as you get home from shopping. Never let meat sit out longer than two hours at room temperature, onehour if the outside temperature if over 90 degrees.

Food should be defrosted in the refrigerator and not on thecountertop. Other defrosting methods, neither of which work well for meat, include submersion in water andusing the microwave. Foods that are marinating should be kept under refrigeration. It is important that therefrigerator temperature be checked regularly. Forty degrees is the optimal refrigeration temperature.

Thereshould be plenty of space for the cool air to circulate within the appliance. Do not over-stuff the refrigerator!

Food StorageSince product dates aren't a guide for safe use of a product, how long can the consumer store the food and stilluse it at top quality? Freeze it if you cannot use it within times recommended on chart. See the accompanying refrigerator charts for storagetimes of dated products.

Foods can develop an off odor, flavor or appearance due to spoilage bacteria. If a foodhas developed such characteristics, you should not use it for quality reasons.

If foods are mishandled, however,food borne bacteria can grow and cause food borne illness -- before or after the date on the package. Forexample, if hot dogs are taken to a picnic and left out several hours, they wouldn't be safe if used thereafter,even if the date hasn't expired. Other examples of potential mishandling are products that have been defrosted atroom temperature more than two hours; cross-contaminated; or handled by people who do not use propersanitary practices.

Make sure to follow the handling and preparation instructions on the label to ensure topquality and safety. LabelingUSDA Mark of Inspection Meat unsound, unhealthful, unwholesome or otherwise unfit or unsafe for food shall not receive a Markof Inspection.

Meat may be adulterated with dyes, chemicals, preservatives, or ingredients, which render suchproduct unfit for human consumption. The commissioner shall seize and destroy for food purposes any meat,meat by-product or meat food product that does not bear an official inspection legend affixed pursuant to afederal inspection.

The transportation of dead animals, properly identified condemned carcasses and parts ofcarcasses and other condemned or inedible products or materials to rendering plants is the only exceptionallowed. It is unlawful for any person to posses, keep or use an inspection legend, stamp simulating theinspection legend or meat label unless authorized to do so.

Meat that is sound, healthful, wholesome and fit for sale and consumption shall receive a Mark ofInspection under a USDA inspection system. If an amenable meat, the mark of inspection shall be a circle,inside which is encrypted the identification number of the slaughtering or processing plant. If a non-amenablemeat, the mark of inspection shall be a triangle, inside which will be encrypted the unique identification numberof the slaughtering or processing plant.

Meat that has been federally inspected and passed for wholesomeness is stamped with a purple markthat is either round for amenable species or triangular for non-amenable species. The purple dye used to stampthe grade and inspection marks onto a meat carcass is made from a food-grade vegetable dye and is not harmful.

The exact formula is proprietary and owned by the maker of the dye. The mark is put on carcasses and majorcuts. After trimming it might not appear on retail cuts such as roasts and steaks. However, meat that is packagedin an inspected facility will have an inspection mark that identifies the plant on the label.

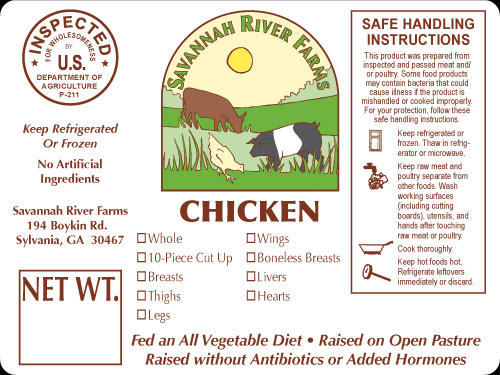

Inspection mark Inspection mark Inspection mark Voluntary raw meat raw poultry processed products Inspection markLabeling of Raw Meat and PoultryThe requirements in the new final rule on Pathogen Reduction and Hazard Analysis and Critical Control Points HACCP are designed to minimize the likelihood of harmful bacteria being present in raw meat and poultryproducts.

However, some bacteria could be present and might become a problem if meat and poultry are nothandled properly. To assist food handlers, USDA requires that safe handling instructions be put on allpackages of raw and not fully cooked meat and poultry. The use of food additives has become more prominent in recent years, due tothe increased production of prepared, processed, and convenience foods.

Additives are used for flavor andappeal, food preparation and processing, freshness, and safety. At the same time, consumers and scientists haveraised questions about the necessity and safety of these substances. Before any substance can be added to food,its safety must be assessed in a stringent approval process. The Food Safety and Inspection Service FSIS ofthe U. Department of Agriculture USDA shares responsibility with FDA for the safety of food additivesused in meat, poultry, and egg products.

All additives are initially evaluated for safety by FDA. When anadditive is proposed for use in a meat, poultry, or egg product, its safety, technical function, and conditions ofuse must also be evaluated by the Labeling and Consumer Protection Staff of FSIS, as provided in the FederalMeat Inspection Act, the Poultry Products Inspection Act, the Egg Products Inspection Act, and relatedregulations.

Although FDA has overriding authority regarding additive safety, FSIS may apply even stricterstandards that take into account the unique characteristics of meat, poultry, and egg products. Additives arenever given permanent approval. FDA and FSIS continually review the safety of approved additives, based onthe best scientific knowledge, to determine if approvals should be modified or withdrawn.

The statutes and regulations to enforce the statutes require certain information on labels of meat andpoultry products so consumers will have complete information about a product. In all cases, ingredients must belisted on the product label, in the ingredients statement in order by weight, from the greatest amount to the least. This is because they are used primarily for theirflavor contribution and not their nutritional contribution. Substances such as dried meat, poultry stock, meatextracts, or hydrolyzed protein must be listed on the label by their common or usual name because their primarypurpose is not flavor.

They may be used as flavor enhancers, binders, or emulsifiers. They must be labeled usingthe species of origin of the additive, for example, dried beef, chicken stock, pork extract, or hydrolyzed wheatprotein. Color additives must be declared by their common or usual names on labels, e.

The labeling requirements help consumers make choices about thefoods they eat. It can also help thepurchaser to know the time limit to purchase or use the product at its best quality. It is not a safety date.

However, if a calendar date is used, it must express both themonth and day of the month and the year, in the case of shelf-stable and frozen products. Althoughdating of some foods is required by more than 20 states, there are areas of the country where much of the foodsupply has some type of open date and other areas where almost no food is dated.

You should buy the product before the date expires. It is not a purchase or safety date. The date has been determined by the manufacturer of the product. Nutrition Labeling The Nutrition Labeling and Education Act of required nutrition labeling of most foods regulatedby the Food and Drug Administration.